My old barrel stove was getting dangerous. I bought it on Craigslist for $25 or $50 almost a decade ago now. It was rusty when I bought it, and all that heat and snow over the years has made it really crumble. To give you an idea of how dangerous it was – at the end of it’s life I had to prop it up with a log (one leg rusted off completely). The log started to catch fire due to small holes in the barrel. Time for something new! 🔥

I got a BSK1000 Camp Stove Kit from Amazon for $60. They’re likely cheaper to get at a local hardware store or farm & fleet warehouse, usually for less than $50: https://www.menards.com/main/heating-cooling/fireplaces-stoves/fireplace-wood-stove-tools-accessories/wood-stove-accessories/united-states-stove-camp-barrel-stove-kit/bsk1000/p-1444445447395.htm

Then I got a barrel off of craigslist. I think it had been used for cooking oil in its previous life because it smelled like a hamburger joint 🍔

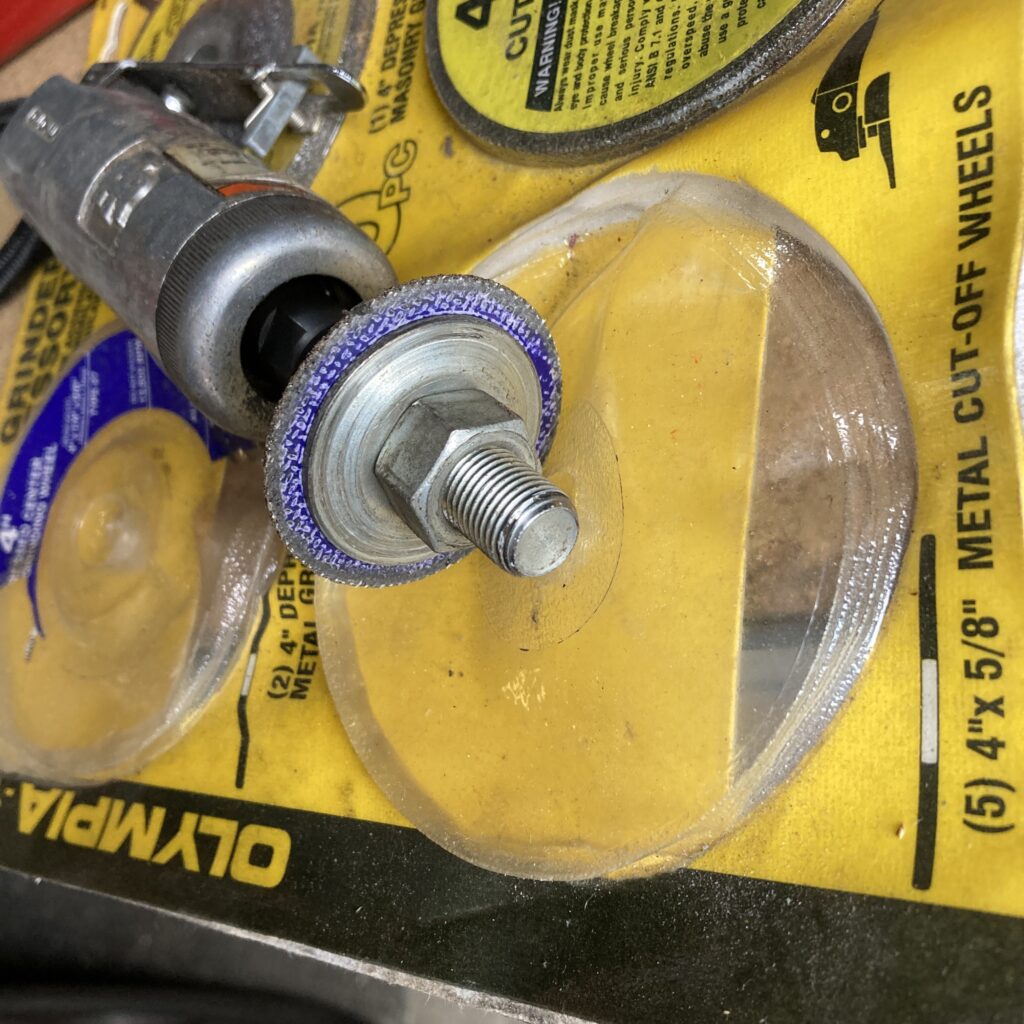

Per the instructions, the vent below the door is supposed to go where the small barrel vent is. I used a metallic sharpie to mark the drill holes and openings. I used a die grinder air tool to cut the openings and a new titanium 1/4″ drill bit for the holes.

I added anti-seize grease to all the nuts and screws in the kit, but I’m not sure if it’s going to help given the temperatures and moisture it will experience. But we’ll see – worse case scenario, if I want to transfer the kit parts to a new barrel, I can use the 1/4″ bit and drill out the screws.

To fasten the legs I put the barrel on its side and blocked it with a couple pieces of wood. I put the seam down b/c that’s where I’m going to do the cutting for the steam trays and chimney. I figure I should remove material at the seam since that’s probably the weakest part of the barrel anyway.

With the barrel chocked into place, I put the legs on and used a level to make sure it would sit flat once I fastened them.

Here you can see my anti-seize paste and an initial cut line I drew to cut out an area for the steam trays.

My old barrel didn’t have the flue installed, so I’m hoping this will be a game changer 🤞The goal is to hold as much heat in the barrel so energy is directed to the boil. Also I added a length of pipe to use as a chimney.

I cut a large section out for the steam trays and used a level to make sure they’d sit as flat as possible when it’s out in the yard.

I used my Ingersoll Rand die grinder air tool to make all of the cuts for the door, chimney, and steam trays. It’s slow going so take your time and be patient. I made several cuts over several days. The cut-off wheel I used was new when I started this job (over 4 1/2″ in diameter) and was probably around 2″ when done.

Final Product

Here’s the new rig in action – the best part is the chimney which keeps the wood smoke overhead. You’ll still smell like a wood fire, just not as bad 😎

Leave a Reply